WQ High Efficiency No Block-up Sewage

Product Overview

WQ Non-clogging submersible fixed highSewage pumpBlocked by anti-pandemic Road, design of hydraulic components, greatly enhance the dirt capacity, effective diameter of 5 times through the pump fiber material and a diameter of about 50% of the pump diameter solid particles. Designed, matching motor and reasonable, high efficiency, energy saving effect is remarkable. Mechanical seal is double tandem seal, made of hard wear-resistant tungsten carbide, a durable, wear, etc., can pump more than 800 hours continuous operation safety. Pump compact, small size, easy to move, easy to install, no need to build pumping stations, into the water can work, greatly reduce the construction cost. Indoor water pumping with the probe, whenPumpSide of the mechanical seal is damaged, the water into the oil chamber, the probe signal occurs, the implementation of the protection of the pump.

According to user needs with automatic safety protectionControl cabinet, On the pump leak, leakage, overload and overtemperature monitoring to ensure safe and reliable pump operation. Double rail automatic coupling installation system, to the installation of the pump installation and maintenance, a great convenience, may not be required to access the sump. Float switch according to the required water level changes. Kai automatic pump stops, no special person to care. In the context of using the lift operation of motor set, however. Motor can be used according to applications outside the third nested loop water cooling system to ensure that pump the water (dry) state of safe operation. Installation with a fixed automatic coupling installation and free installation of two kinds of mobile can be used to meet different situations. QW-type structure shows no plugSubmersible sewage pumpBy the motor and pump two parts, both through the oil separation chamber and the mechanical seal components separated by an electromechanical integration products, motor and pump combined with the same axis (rotor) pumps throughout the length of the short, compact structure.

Equipped with multiple protection devices, makes pump reliable,

Its role as the main components: the signal line 1: pump control cabinet with full protection, the protection of the pump all directions, including leakage, phase, short circuit, overheat, motor overload and other projects. Stator 8: Using B-or F-class insulation . Leak probe 11: The device installed in the oil chamber, when the mechanical seal is damaged, the water into the oil chamber, the probe may issue a signal from the control system implemented to protect the pump. Mechanical seal 13: Road tandem double seal, use anticorrosive hard tungsten carbide material, with the sealing reliability, wear-resistant, long service life. Impeller 17: impeller single or dual channel flow structure, with strong capacity, through large fiber waste materials and reduce congestion, winding fault. Pump 15: The impeller is equipped with, makes the pump with high efficiency. Seal ring 18: Sandy Bay Office installed in the pump body, impeller because when I run Ershi Central Office wear seal rings can be replaced to ensure optimum efficiency pump to run.

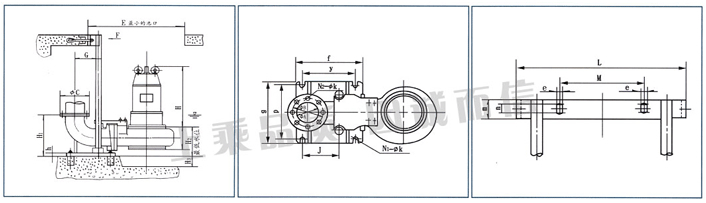

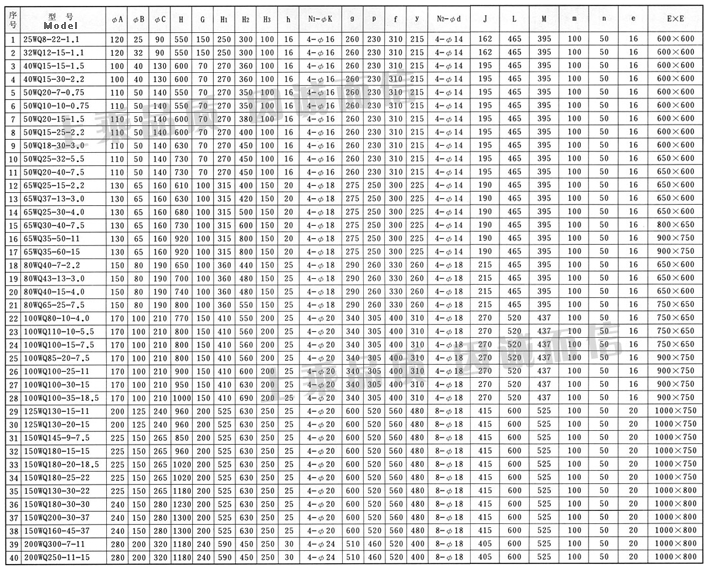

installation size

installation size and dimension

Performance Parameters

| Model | Head | Specification | Flow | Nature | Power (KW) |

Speed (R / min) |

Voltage (V) |

||

| Caliber (Mm) |

Flow (M3 / h) |

Head (M) |

|||||||

| 25-8-22 | 25 | 8 | 22 | 1.1 | 2900 | 380 | |||

| 32-10-15 | 32 | 10 | 15 | 1.5 | 2900 | 〃 | |||

| 40-15-30 | 40 | 15 | 30 | 2.2 | 1900 | 〃 | |||

| 50-20-7 | 50 | 20 | 7 | 0.75 | 1450 | 〃 | |||

| 50-20-15 | 50 | 20 | 15 | 1.5 | 2900 | 〃 | |||

| 50-15-25 | 50 | 15 | 25 | 2.2 | 2900 | 〃 | |||

| 50-18-30 | 50 | 18 | 30 | 3 | 2900 | 〃 | |||

| 65-25-15 | 65 | 25 | 15 | 2.2 | 2900 | 〃 | |||

| 65-25-30 | 65 | 25 | 30 | 4 | 2900 | 〃 | |||

| 80-40-7 | 80 | 40 | 7 | 2.2 | 1450 | 〃 | |||

| 80-40-15 | 80 | 40 | 15 | 4 | 2900 | 〃 | |||

| 80-65-25 | 80 | 65 | 25 | 7.5 | 2900 | 〃 | |||

| 100-85-10 | 100 | 85 | 10 | 4 | 1450 | 〃 | |||

| 100-100-15 | 100 | 100 | 15 | 7.5 | 1450 | 〃 | |||

| 100-85-20 | 100 | 85 | 20 | 7.5 | 1450 | 〃 | |||

| 100-100-25 | 100 | 100 | 25 | 11 | 1450 | 〃 | |||

| 100-100-35 | 100 | 100 | 35 | 15 | 1450 | 〃 | |||

| 125-115-15 | 125 | 115 | 15 | 15 | 1450 | 〃 | |||

| 150-180-15 | 150 | 180 | 15 | 15 | 1450 | 〃 | |||

| 150-180-20 | 150 | 180 | 20 | 18.5 | 1450 | 〃 | |||

| 150-180-30 | 150 | 180 | 30 | 22 | 1450 | 〃 | |||

| 150-180-35 | 150 | 180 | 35 | 30 | 1450 | 〃 | |||

| 200-300-10 | 200 | 300 | 10 | 11 | 980 | 〃 | |||

| 200-300-15 | 200 | 300 | 15 | 22 | 1450 | 〃 | |||

| 200-300-20 | 200 | 300 | 20 | 30 | 1450 | 〃 | |||

| 200-300-25 | 200 | 300 | 25 | 37 | 1450 | 〃 | |||

| 250-600-10 | 250 | 600 | 10 | 30 | 980 | 〃 | |||

| 250-600-12 | 250 | 600 | 12 | 37 | 1450 | 〃 | |||

| 250-600-15 | 250 | 600 | 15 | 45 | 1450 | 〃 | |||

| 250-600-20 | 250 | 600 | 20 | 55 | 1450 | 〃 | |||

| 250-600-25 | 250 | 600 | 25 | 75 | 1450 | 〃 | |||

| 300-800-12 | 300 | 800 | 12 | 45 | 980 | 〃 | |||

| 300-480-15 | 300 | 480 | 15 | 45 | 1450 | 〃 | |||

| 300-600-20 | 300 | 600 | 20 | 55 | 1450 | 〃 | |||

| 300-800-20 | 300 | 800 | 20 | 20 | 1450 | 〃 | |||

Lowest Prices GuaranteedPrices Audited Daily by You

Lowest Prices GuaranteedPrices Audited Daily by You Free & Fast DeliveryIn Partnership wtih

Free & Fast DeliveryIn Partnership wtih Confidential & DiscreetShop at Home with Privacy

Confidential & DiscreetShop at Home with Privacy Thousands of Satisfied CustomersWhat They Say About Us

Thousands of Satisfied CustomersWhat They Say About Us